Description

Features

Adaptable Application: Perfectly suited for all steel surfaces, especially in places where in-depth cleaning or sandblasting might be a challenge.

Theoretical Spread Rate: Offers an impressive coverage of 150-250 sq.ft/gal at a slim 1mil thickness.

Application Methodology: Though the removal of loose rust with a wire brush is advocated, spray application of MT-101 is optimal for deep rust penetration. It’s versatile enough for both dry and damp surfaces, and for maximum protection, a subsequent coat is recommended within 30-60 minutes of the initial application. Post an 8-12 hour drying period, the surface becomes ready for a topcoat.

Benefits

- Quick and efficient rust conversion adaptable to a range of weather conditions.

- Guarantees over 800 hours of corrosion defense with just a 1-mil application under Salt Spray conditions (ASTM B 117) on pre-rusted steel parts.

- Retains its protective properties even in significant salt-contaminated environments.

- Acts as a robust barrier against re-rusting and notably enhances the adherence of top-coats.

- Eco-conscious with VOC and AQMD compliance, ensuring a non-toxic, eco-friendly constitution.

What Sets MT-101 Apart?

- Its non-flammable, non-combustible, and non-corrosive nature ensures zero harm to metal, plastic surfaces, or welds.

- A water-based composition with an almost non-existent VOC footprint.

- Requires minimal surface preparation, yet offers formidable re-corrosion prevention for up to a year.

- Completely devoid of caustics or petroleum distillates, making it a safe choice for various applications.

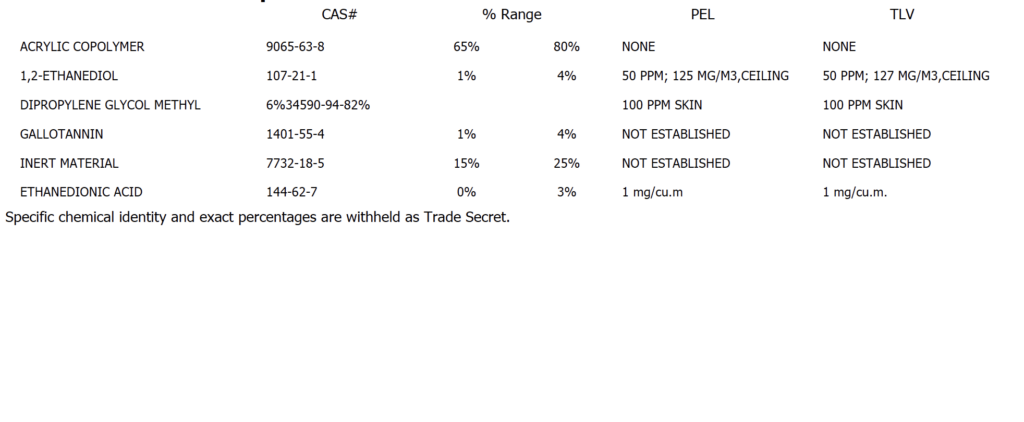

Technical Specs:

- Flash Point (CCP): Non-Flammable

- Boiling Point: 210 F

- Vapor Pressure: Not Applicable

- Vapor Density: Greater than Air (Air=1 >1)

- Specific Gravity: 1.06

- Water Solubility: Complete

- Appearance: White liquid with a subtle odor.

- PH: Not Determined

MT-101 Applications

List of usage and application scenarios for the MT-101 Product

MT-101 Usage in Aerospace

In the cutting-edge aerospace sector, MT-101 stands as a formidable guardian against the detrimental effects of rust and environmental degradation. This solution offers a robust shield for aircraft exteriors, jet engine components, landing gears, and even intricate cockpit instruments. Whether it’s safeguarding spacecraft exteriors, drones, or the vast array of aerospace testing equipment, MT-101 ensures that these high-value assets remain unaffected by rust, giving them enhanced longevity and ensuring optimal performance in the demanding conditions of air and space.

- Aircraft Exterior protection.

- Jet Engine Components rust prevention.

- Landing Gears rust prevention.

- Cockpit Instruments shielding.

- Aerospace Manufacturing Equipment protection.

- Spacecraft Exteriors rust control.

- Cargo Bays and Holds protection.

- Satellites anti-rust coating.

- On-board Computers and Electronics protection.

- Aerospace Testing Equipment rust prevention.

- Helicopter Rotors rust protection.

- Aircraft Windows and Canopies anti-rust coating.

- Drones exterior protection.

- Hangar Infrastructure rust prevention.

- Runway Lights and Equipment protection.

- Aircraft Interiors rust shielding.

- Fuel Tanks rust control.

- Communication Equipment rust protection.

- Space Station Modules protection.

- Missile and Rocket Components rust prevention.

MT-101 Usage in Marine

The marine environment, characterized by its saline ambiance and challenging conditions, meets its match in MT-101. This product is adept at ensuring ship hulls remain impervious to the corrosive touch of seawater. Offshore platforms, marine equipment, underwater submersibles, and even the docks & piers that anchor marine life to the shore find themselves guarded against rust. MT-101 ensures that the vast realm of marine structures and vessels remain robust and corrosion-free, allowing them to sail smoothly through both calm and stormy waters.

- Ship Hulls rust prevention.

- Offshore Platforms rust protection.

- Marine Equipment rust control.

- Underwater Submersibles protection.

- Docks & Piers rust prevention.

- Buoyancy Devices rust control.

- Marine Containers protection.

- Fishing Vessels rust prevention.

- Marine Propulsion Systems protection.

- Underwater Cables rust control.

- Aquaculture Infrastructure protection.

- Marine Railways and Boat Lifts rust prevention.

- Navigational Equipment protection.

- Diving Equipment rust control.

- Anchor Chains and Accessories protection.

- Marine Tunnels and Underwater Constructions rust prevention.

- Seawalls and Breakwaters protection.

- Yacht Exteriors rust control.

- Research Vessels rust prevention.

- Safety Barriers and Fences rust protection.

MT-101 Applications in Construction

MT-101 redefines the standards of protection in the construction industry, a field where the strength and longevity of materials are paramount. As construction sites grapple with the relentless threats of moisture, environmental factors, and wear-and-tear, MT-101 emerges as a trusted solution. It offers unwavering protection to steel frameworks, scaffolding, concrete reinforcements, and even the very tools that bring structures to life. With MT-101, structures stand taller, stronger, and resist the test of time by preventing rust before it can even take root.

- Steel framework protection in buildings and bridges.

- Scaffolding components exposed to environmental elements.

- Roofing materials, especially metal-based.

- Concrete reinforcements and their steel structures.

- Pipelines and plumbing in construction sites.

- Ventilation systems and their metal components.

- Construction barriers and safety equipment.

- Outdoor lighting fixtures and their metal bases.

- Elevators, escalators, and their associated machinery.

- Foundation protection of buildings and structures.

- Brick and masonry metal fixtures.

- Window frames and metal fittings.

- Construction cranes and their associated machinery.

- Construction tools exposed to moisture and chemicals.

- Bridges, overpasses, and their associated equipment.

- Tunnels and their metallic components.

- Parking garages and their steel structures.

- Storage facilities, especially metal-based.

- Safety equipment used in construction sites.

- Metal-based fittings in public utility structures.

MT-101 Usage in Oil and Gas

The oil and gas sector, renowned for its harsh environments and critical operations, finds a reliable ally in MT-101. From the depths of offshore rigs to the vast stretches of pipelines, and from the heart of refineries to the expanse of storage tanks, MT-101 acts as a formidable rust converter and protector. It stands resilient against the challenges posed by salty waters, moisture, and the constant threat of corrosion, ensuring that essential equipment remains operational, safe, and rust-free, thereby optimizing production and minimizing downtime.

- Pipeline protection against rust and corrosion.

- Drilling equipment exposed to harsh elements.

- Storage tanks to prevent internal and external rust.

- Offshore rigs and their metallic components.

- Refinery infrastructure, especially those close to the sea.

- Pump equipment handling oil and other chemicals.

- Valves, fittings, and associated machinery.

- Gas compressors and their outer casings.

- Heat exchangers used in refining processes.

- Oil well casings and their protective structures.

- Control systems and their metallic housings.

- Subsea equipment constantly exposed to saline water.

- Fracking equipment and its associated machinery.

- Gas processing units and their infrastructures.

- Safety barriers and fences in oil fields.

- Derricks and hoisting equipment in drilling sites.

- Oil and gas transportation tankers.

- LNG carrier ship components.

- Gas collection and distribution networks.

- Equipment in natural gas purification plants.

FAQ

Contact us for the most accurate and up-to-date information.

MT-101 is a chemical solution designed to combine with rust, creating a durable shell that protects against oxygen and moisture effects, offering up to 1 year of rust-free protection.

Absolutely! MT-101's robust rust-protection capabilities make it ideal for sectors like aerospace, marine, construction, and oil & gas, ensuring metal components remain rust-free under demanding conditions.

First, remove any loose rust with a wire brush and clean the surface. MT-101 can be sprayed or brushed on, with spray application preferred for better penetration. It's applicable to both dry and damp surfaces. A second coat is recommended within 30-60 minutes of the first for optimum protection.

After applying MT-101, it's recommended to allow it to dry for 8-12 hours before applying any topcoat.

Yes, MT-101 is environmentally friendly, non-toxic, non-reactive, non-corrosive, and non-flammable. Its water-based formulation means it doesn't contain harmful caustics or petroleum distillates.

MT-101 chemically combines with the rust, transforming it into a nearly indestructible shell. This unique bond prevents the harmful effects of oxygen and moisture, thereby preventing re-rust for up to a year.

No, MT-101 is non-corrosive, ensuring that it will not harm metal or plastic surfaces. It also won't damage or contaminate metals or welds.

Yes, MT-101 adheres to VOC and AQMD standards, making it compliant with rigorous environmental safety regulations.

Request for Quotation

Fill the following form to request a quotation and our sales team will contact you within 24 hours.