Description

MT-1 goes beyond just rust prevention. With an innate UV resistance, this non-flammable rust inhibitor enhances UV protection to painted surfaces, ensuring longevity even under harsh environmental conditions. Impressively, MT-1’s resilience against abrasion surpasses NAVSEA standards, losing just 1% during rigorous tests, setting it distinctly apart from competitors. MT-1’s transformative nature is evident not only in its clear variant but also in its ability to incorporate color, making it an ideal alternative to traditional epoxy coatings. Suitable for a myriad of surfaces, including metals, masonry, timber, and fiberglass, MT-1 stands as the epitome of cutting-edge protective coatings.

Features

- Fire-Safe: MT-1 doesn’t catch fire.

- UV Guard: It acts like a sunblock for painted areas.

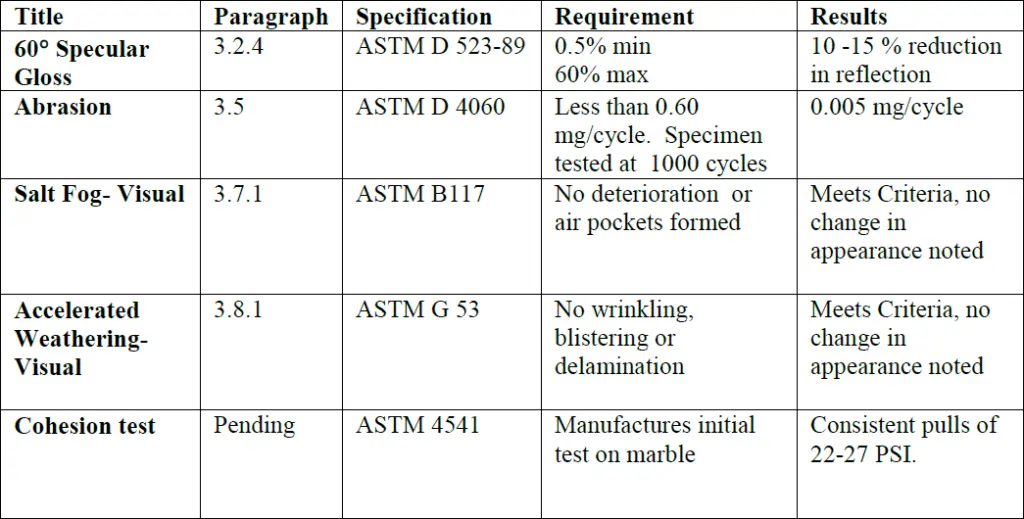

- Tough as Nails: It sailed through NAVSEA abrasion tests with just 1% loss, outperforming many regular standards.

- Super Bond: MT-1 attaches to surfaces 10 times better than most paints.

- Customizable Look: It’s typically clear but can be tinted to replace epoxy paints in any color you fancy.

Benefits

- Eco-friendly: It meets California’s strict environmental standards.

- Quick Set: It dries in just 1.5 hours and is fully set in 5.

- Long Life: Its super bonding power ensures it lasts longer than regular coatings.

- Robust for Rough Jobs: It’s tough enough for the demanding conditions of oil and gas exploration.

- Saves Time & Money: MT-1’s durability means less time and money spent on maintenance.

What Sets MT-1 Apart?

- Blocks UV rays.

- Stands up to impacts – no damage even at 160PSI.

- Resists wear and tear.

- Bonds incredibly well – in tests, it even pulled marble!

- Holds strong against chemicals.

- Environmentally sound and not solvent-based.

- Safe: non-flammable and non-toxic.

- Fast: Dries in 90 minutes, sets in 8 hours.

- Long-lasting shine with clear MT-1. Also available in various colors.

- Keeps rust at bay in all conditions.

- Provides multi-year protection.

Technical Specs:

- Type: Solvent-based

- Pigment: Solvent Pigment

- Volume: 20% Solids

- Thickness/Coverage: Wet: 3.5-5 mils; Dry: 20 mils; Coverage: 13-16 sq. m./L

- Drying Time: Tack-free in 30 mins; Fully cured in 8 hours

- Temperature Range: Application: 100 C – 32.20 C; Operating: 400 C – 1210 C

MT-1 Applications

List of usage and application scenarios for the MT-1 Product

MT-1 Usage in Aerospace

Given MT-1’s unique properties, it can be a game-changer in the aerospace sector, enhancing the durability and lifespan of various components. Here are couple of usage scenarios for MT-1 in Aerospace sector:

Aircraft Exterior: Protects the aircraft’s outer skin from corrosion, UV degradation, and harsh weather conditions.

Cockpit Instruments: Provides a protective coat to prevent corrosion and wear in critical instruments.

Landing Gears: Protects from corrosion due to varied environments during landings and take-offs.

Jet Engine Components: Acts as a heat and corrosion-resistant layer for engine parts.

Spacecraft Exteriors: Shields against UV rays, potential space debris, and the harsh environment of space.

Cargo Bays and Holds: Protects from potential rust and wear from regular loading and unloading of cargo.

Fuel Tanks: Ensures no corrosion impacts the purity of jet fuel.

Satellites: Protects satellite exteriors from space environment-related wear and potential impact damage.

Communication Equipment: Guards against wear and tear due to constant exposure to varying conditions.

Drones: Enhances the lifespan of drones by protecting against environmental factors.

Hangar Infrastructure: Protects hangar structures, especially in coastal areas where salt can cause rapid degradation.

Runway Lights and Equipment: Ensures longer life and lesser maintenance for essential runway equipment.

On-board Computers and Electronics: Adds an extra layer of protection against potential moisture and environmental factors.

Aircraft Interiors: Enhances the durability of seat structures, overhead bins, and other components exposed to frequent use.

Aerospace Testing Equipment: Protects equipment used in R&D, ensuring accurate results over extended usage.

Helicopter Rotors: Shields rotors from the environment and potential corrosion, enhancing lifespan.

Aircraft Windows and Canopies: Provides an extra layer of UV protection, ensuring clear visibility and protection over extended periods.

Aerospace Manufacturing Equipment: Prolongs the life of machines and tools used in the manufacturing process.

Missile and Rocket Components: Enhances the resilience of parts exposed to high heat and extreme conditions during launch and flight.

Space Station Modules: Provides protection against space debris, UV rays, and the extreme environment of space.

MT-1 Usage in Marine

Seas and oceans can be harsh. MT-1 helps ships, boats, and docks stand up to the challenges of salt, water, and sun. Whether it’s ship hulls or piers, they stay stronger and look better for longer:

Ship Hulls: Provides a protective barrier against saltwater, UV radiation, and potential abrasions from underwater debris or docking.

Offshore Platforms: Shields structures from the corrosive marine environment, ensuring a longer lifespan and reduced maintenance.

Marine Equipment: Protects tools and machinery exposed to the elements, from winches to cranes.

Underwater Submersibles: Enhances resistance against high pressure, salinity, and potential underwater obstacles.

Docks & Piers: Preserves the integrity of these structures against weathering, sea organisms, and regular wear and tear.

Buoyancy Devices: Ensures that buoys, flotation devices, and life rafts are protected against UV degradation and saltwater corrosion.

Marine Containers: Protects against rust and corrosion, ensuring the safe transport of goods.

Fishing Vessels: Provides protection from the harsh marine environment and ensures longevity of the vessel.

Desalination Systems: Shields machinery and pipelines from the corrosive effects of salt and other minerals.

Marine Propulsion Systems: Guards engines and propellers against potential damage from saltwater and debris.

Underwater Cables: Protects communication and power cables from saltwater corrosion and potential physical damages.

Aquaculture Infrastructure: Ensures that equipment used in fish farms and other marine farming remains rust-free and durable.

Marine Railways and Boat Lifts: Shields these structures from regular exposure to saltwater and potential abrasions.

Navigational Equipment: Protects devices and tools from the elements, ensuring accurate navigation.

Diving Equipment: Guards against rust and corrosion, extending the lifespan of diving gears and tools.

Anchor Chains and Accessories: Enhances resistance against rust, ensuring that anchors maintain their strength and reliability.

Marine Tunnels and Underwater Constructions: Provides a barrier against the continuous exposure to saltwater and marine life.

Seawalls and Breakwaters: Ensures these protective barriers remain robust and effective against the force of waves and potential erosive elements.

Yacht Exteriors: Shields luxury boats from UV rays, saltwater, and other potential damages ensuring a pristine appearance.

Research Vessels: Protects these vessels that often venture into extreme marine environments, ensuring their longevity and safety.

MT-1 Applications in Construction

Incorporating MT-1 in the construction sector can greatly benefit the longevity and safety of structures, tools, and machinery. The reduction in maintenance needs can also translate to significant cost savings over time:

Heavy Machinery: Protect construction vehicles and equipment from rust, ensuring a longer lifespan and reducing maintenance costs.

Steel Framework: Guard steel structures from corrosion, especially in areas exposed to moisture or aggressive environmental conditions.

Scaffolding: Enhance the durability of temporary structures against the elements, ensuring worker safety.

Construction Tools: Protect tools like drills, hammers, and saws from the elements and extend their working life.

Concrete Reinforcements: Prevent the corrosion of metal reinforcements within concrete structures.

Roofing Materials: Offer protection from UV radiation, reducing wear and tear on roof surfaces.

Pipelines and Plumbing: Shield pipes from corrosion, particularly in areas where the water might have a high mineral content.

Brick and Masonry Sealant: Use as a sealant for brick walls and other masonry to protect against moisture infiltration.

Foundation Protection: Prevent moisture and rust from affecting the foundational structures of buildings.

Window Frames and Metal Fittings: Protect against wear, ensuring longevity and aesthetic appeal.

Elevators and Escalators: Shield mechanical parts from wear and potential rust.

Ventilation Systems: Guard against rust in HVAC systems, ensuring efficient operation.

Construction Barriers: Coat barriers and fences used around construction sites to protect them from weathering.

Outdoor Lighting Fixtures: Protect against rust and ensure continued functionality despite exposure to the elements.

Bridges and Overpasses: Enhance resistance against environmental factors, especially in areas prone to saltwater spray or road salts.

Tunnels: Protect the metal components from moisture and potential corrosive elements.

Construction Cranes: Guard these vital machines from environmental wear, ensuring their safe operation.

Safety Equipment: Coat items like metal safety harnesses and railings to prevent rust and ensure optimal safety.

Parking Garages: Protect metal barriers, gates, and railings from daily wear and exposure.

Storage Facilities: Shield metal components of storage units from rust, ensuring the safety and security of stored items.

MT-1 Usage in Oil and Gas

In the challenging world of oil and gas, MT-1 stands tall. It wraps equipment in a protective layer, helping them resist damage and wear. That means fewer repair breaks and more working time. Samples of MT-1 usage in the Oil and Gas sector:

Pipeline Protection: Provides a barrier against corrosion, especially for pipelines located underwater or in corrosive soil conditions.

Drilling Equipment: Shields drilling machinery from wear and tear caused by abrasive materials encountered during the drilling process.

Storage Tanks: Protects against rust and corrosion, ensuring the purity of stored oil or gas.

Offshore Rigs: Offers protection from the harsh marine environment, saltwater, and UV degradation.

Refinery Infrastructure: Ensures equipment longevity and safety by resisting corrosive chemicals used in refining processes.

Pump Equipment: Extends the lifespan of pumps by offering a protective layer against rust and wear.

Valves and Fittings: Provides an additional layer of protection against leaks and breaks.

LNG Carriers: Protects the storage units from both internal and external factors, ensuring safe transportation of liquefied natural gas.

Floating Production Units: Ensures that the unit’s exterior remains intact and unaffected by the marine environment.

Transportation Tankers: Shields the exteriors and interiors from potential corrosion due to varying qualities of crude oil.

Gas Compressors: Enhances the lifespan by offering protection against wear and the elements.

Heat Exchangers: Shields against potential external damage and ensures efficient operation.

Oil Well Casings: Offers protection against corrosive elements found deep within the earth.

Control Systems: Protects electronic systems and interfaces from potential damage due to environmental exposure.

Subsea Equipment: Provides an added layer of protection for equipment operating under the ocean, exposed to saltwater and high pressures.

Desalination Systems: Ensures that the systems remain corrosion-free, especially given the high salt content they deal with.

Fracking Equipment: Shields machinery from the aggressive chemicals and conditions used in the hydraulic fracturing process.

Gas Processing Units: Protects against the corrosive elements present in raw natural gas.

Derricks and Hoisting Equipment: Enhances resilience against the elements and regular wear and tear.

Safety Barriers and Fences: Protects against rust and environmental wear, ensuring that safety measures remain intact.

FAQ

Contact us for the most accurate and up-to-date information.

Yes, MT-1 is versatile and can be applied on a variety of surfaces including ferrous & non-ferrous metals, masonry, timber, fiberglass, glass, and carbon fiber.

MT-1 is typically clear, but colors can be added to make it a complete replacement for epoxy coatings, offering both protection and aesthetic appeal.

MT-1 dries within 90 minutes and fully cures in 5 hours. This ensures a quick application process and minimal downtime for the equipment or structure being coated.

Absolutely! MT-1 is fully compliant with California VOC requirements, making it environmentally friendly. Additionally, it's non-flammable and non-toxic.

MT-1 boasts superior bonding power, being 10 times more adhesive than many standard paints available on the market today. It even outperforms many epoxy paints in bonding efficacy.

Yes, MT-1 should be applied at temperatures between 100°C – 350°C. It's important not to apply the product if rain is expected within the next 12 hours or if the surface is wet. Always refer to the technical data for precise application conditions.

Before applying MT-1 on bare metal, conduct an SSPC-1 cleaning to ensure all contaminants are removed. Once this is completed, blast the area to achieve a near white metal finish and remove all grit and dust. The surface should be wiped with Isopropyl Alcohol until no residue is present. After preparation, MT-1 Primer can be applied following the recommended steps.

Request for Quotation

Fill the following form to request a quotation and our sales team will contact you within 24 hours.